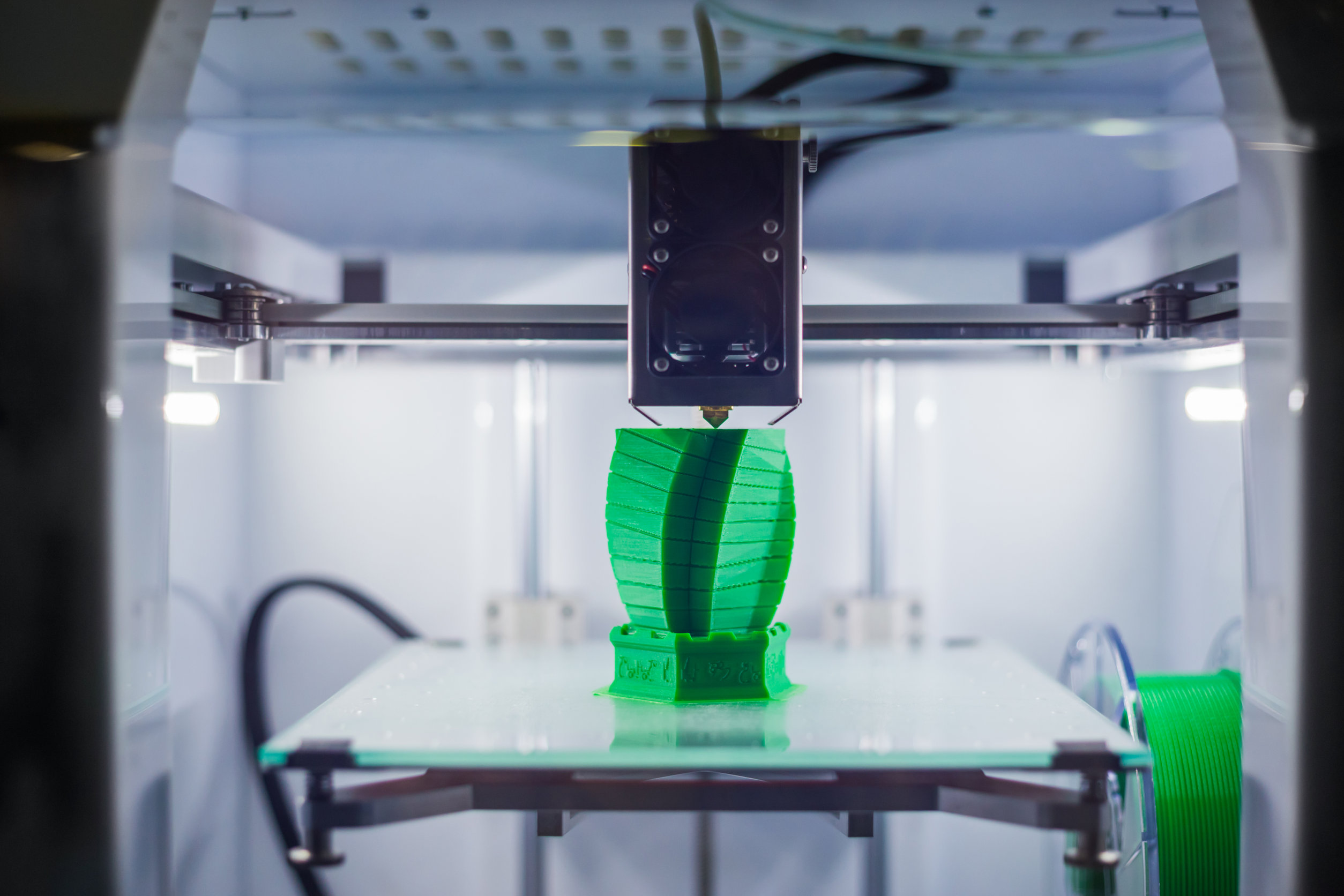

3D printing is all the rage these days, but for the manufacturing industry in particular, this technology offers a wide array of benefits. In this post, we’ll discuss the advantages of 3D printing and how this technology can assist in the prototyping and production processes.

Custom Design

Using computer-aided design (CAD) software, manufacturers can create a product design that can later be sent to a 3D printer. The end result is the limitless ability to create custom-tailored product designs.

Fast, Efficient Prototyping

Before a company mass-produces a product, it must first build a prototype. With a 3D printer, designers can move seamlessly from design to finished prototype.

Because the process is computerized, there is often less waste involved in prototype production. If the initial prototype is found to be insufficient, designers can quickly go “back to the drawing board” to make any necessary adjustments.

Ability to Replicate Ideas Easily

3D printers work off of a CAD file, which means that anyone with that file and a 3D printer can generate a prototype. This makes it easier than ever to share your ideas with others and to collaborate on a final design.

Reduce Costs

The 3D printing process eliminates the need for many other types of tools and techniques that were traditionally involved in the prototyping process. It also offers companies the option to eliminate man-hours that may otherwise be involved in creating a physical product.

For this reason, 3D printers can be more cost-effective than other forms of production.

Where Can I Find 3D Printing Services Near Me?

At RJ Manufacturing, we use photopolymer resins that are resistant to stress and extreme temperatures, giving you access to some of the most advanced 3D printing services in the industry today. Contact us to learn more. We can turn your two-dimensional design into a three-dimensional reality.