Once you have an idea for a product, you have to start the process of bringing it into reality. There are many small steps that have to be taken to lead you to that ultimate goal; but with the help of a full service engineering and manufacturing firm, we can help you get to where you’re going at the least cost possible.

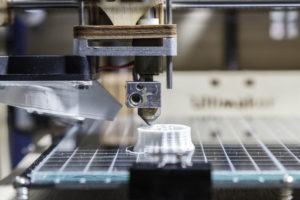

What is SLA 3D printing?

Stereolithography is the oldest form of 3D printing and was actually created in the early 1980s. Today this method of printing is used for many industries, including the medical industry. This is because the SLA printer is able to be much more precise, and the hardened resin allows for actual moving parts, as well as watertight seals.

There are many products that can benefit from hard resin parts or products; but for us, this is just one step in the journey. Your final product will be made from the best materials for the job. The SLA 3D model or prototype allows us to find flaws in the engineering and manufacturing process early, before serious money has been put into the project with machining.

Perfect for molded parts and products with clean surfaces

The preciseness of the 3D printer far surpasses that of PLA 3D printing or other methods. Although the resin will break down and crumble over time, it is an excellent way to introduce a product before resources are available for actual manufacturing to begin. In addition to product demonstrations, these 3D resin models are great for:

- Concept mockups

- Parts with hard angles and complex geometries

- Figurines

Because there is no thermal expansion during the fusing of the layers, the UV lasers are so accurate that you can create high precision working models at a fraction of the cost. You can then move to more suitable materials for the next stage.

If you are ready to take control of your product, contact us today.